In the fast‑moving world of packaging, every second and every watt counts. Operators are constantly searching for ways to cut costs, slash downtime, and boost throughput without compromising product quality. One often overlooked component that can deliver both economic and performance gains is the gear motor. By replacing or upgrading conventional drive systems with intelligent gear motors, packaging plants can slash energy bills, reduce maintenance, and improve automation flexibility—all leading to a healthier bottom line.

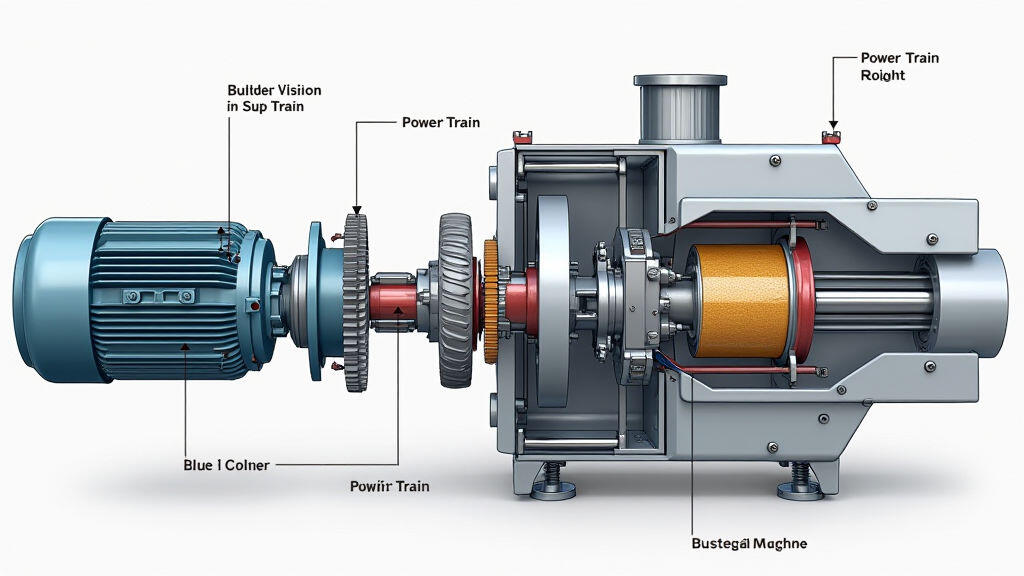

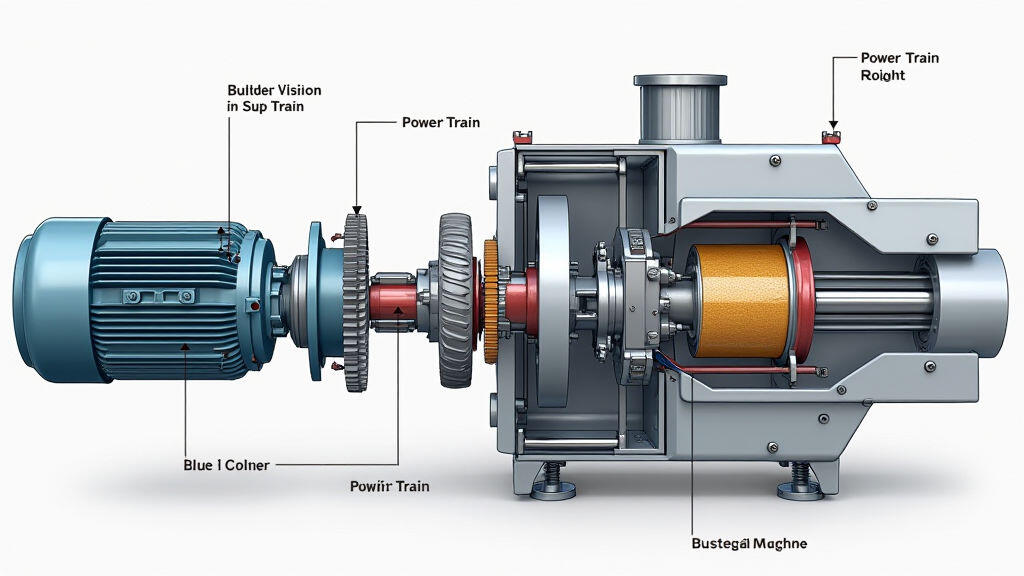

A gear motor is a compact unit that combines an electric motor with a set of gears in a single enclosure. Unlike a free‑running motor that delivers high speed and low torque, the gear motor provides a lower speed but much higher torque, which is ideal for moving heavy loads or driving complex machinery. The gear train—usually a spur or planetary configuration—reduces the motor’s rotation by a fixed ratio, allowing precise control over the movement of packaging equipment such as filling machines, palletizers, or conveyors.

Packaging equipment often relies on variable‑speed drives to adjust fill volumes or pallet stacking heights. Without a good torque source, changes in load can cause jerky motion, increased wear, and higher energy draw. Gear motors solve these problems by:

•

- Delivering consistent torque throughout the operation

- Simplifying drive architecture (motor and gearbox in one package)

- Reducing the need for large, costly drives and heavy-duty bearings

- Offering built‑in protection (over‑speed, over‑current) that cuts maintenance.

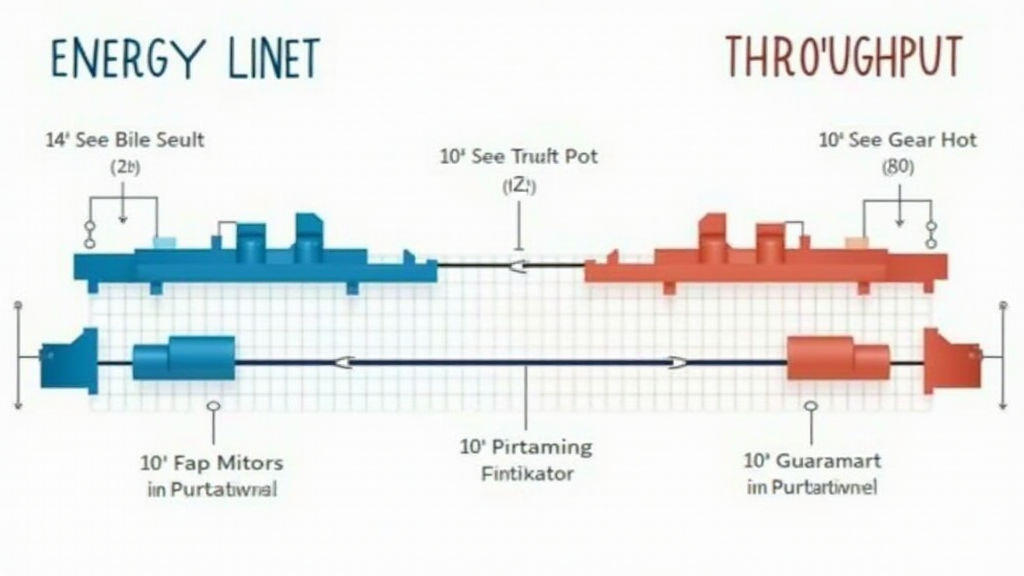

1. Energy Efficiency – A properly selected gear motor runs at its optimal speed, so the motor does not have to waste power overcoming inertia. This translates into a 10–20 % drop in electricity bills on the same line.

2. Lower Maintenance – Fewer moving parts mean fewer replacement parts and shorter service intervals. On high‑throughput lines, this can save thousands annually in labor and spare‑part costs.

3. Reduced Footprint – By integrating the motor and gearbox, plant owners can save valuable floor space that might otherwise be occupied by larger drives. This space can be repurposed for additional inventory or equipment upgrades.

Gear motors give packaging equipment smoother acceleration and deceleration. That reliability translates into:

• Higher Throughput—Shorter cycle times as the motor’s torque profile keeps conveyors moving evenly.

• Precision Control—The fixed gear ratio offers accurate positioning for fill levels, pallet heights, and labeling actions.

• Seamless Integration with PLCs—Modern gear motors come with programmable outputs for start/stop, limit‑switch signals, and fault reporting.

At a mid‑sized cereal manufacturer, the shift from a standard AC motor to an inline gear motor on its filling line cut energy use by 12 % and reduced downtime from 5 % to 2 % of total operational hours. Similarly, a beverage company installed gear motors on its bottling robots, allowing the robots to adapt quickly to different bottle sizes. The result was a 15 % increase in throughput and a 25 % drop in mechanical wear.

As the packaging sector embraces Industry 4.0, gear motors are evolving beyond static speed/torque offerings. Modern models feature embedded sensors that monitor temperature, vibration, and load. These data points feed into cloud‑based analytics, enabling predictive maintenance and real‑time process optimization. With the rise of sustainable packaging—thanks to lighter materials and tighter tolerances—gear motors will underpin the flexibility required to switch between high‑speed, low‑torque and heavy‑load, high‑torque operations seamlessly.

Gear motors may seem like a minor component, but their impact on packaging equipment is profound. By delivering efficient torque, reducing maintenance, and enhancing automation, they help plant operators cut costs and run lines more smoothly. For companies looking to stay competitive in today’s high‑speed, high‑quality marketplace, incorporating modern gear motors is not just an upgrade—it’s a strategic investment. As technology advances, these compact powerhouses will become even more integral to sustainable, data‑driven packaging operations.

Leave A Reply

Your email address will not be published. Required fiels are marked